When a part you've ordered lands on your doorstep in its cardboard box, the simple packaging and unceremonious delivery can make this element of modern life seem unremarkable. But stop to consider the full breadth and scale of the logistics it takes to get that completed item to you, and the complexity of supply chain management comes into focus.

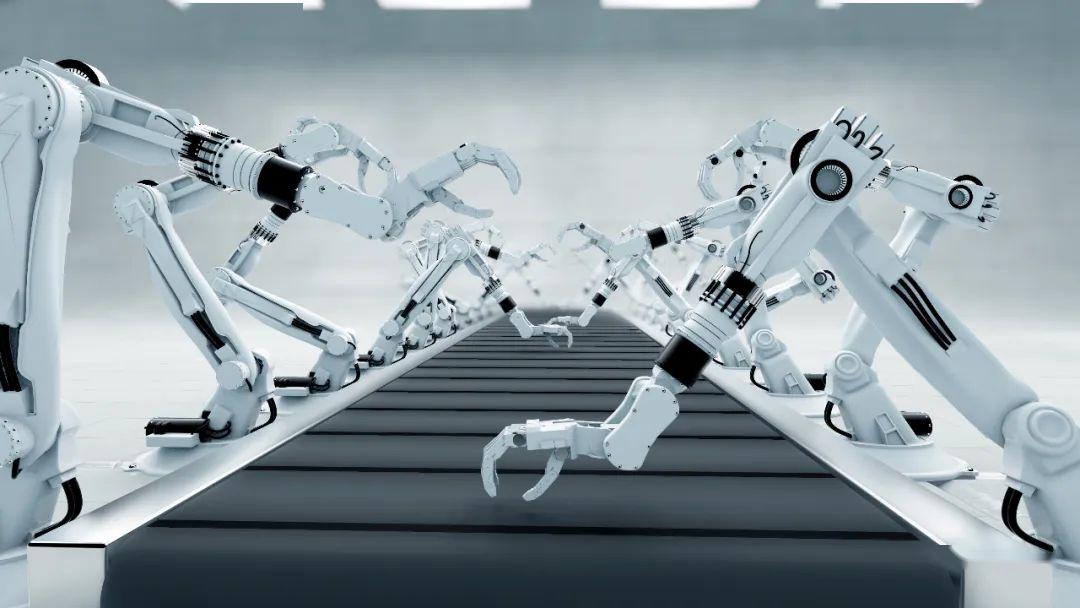

Involves the entire supply chain process, from product design and procurement of raw materials to delivery of the final product and after-sale customer service. In the early days of retail, the steps in this process were siloed, each handled separately with little sense of how one related to the other. But as business operations have become more sophisticated and technology advanced, the conception of the supply chain evolved into a dynamic end-to-end vision encompassing supplier management, scheduling, production, and distribution.

The main difficulty is determining how to weave all the stages of a supply chain into a seamless system. What are the tools and techniques that make a potentially unwieldy series of stages become self-responsive, dynamic, and flexible enough to bend against challenges without breaking? How do you develop full supply chain visibility so your workforce is empowered with valuable real-time data? Beyond the goals of efficiency and more confident decision-making, effective management of an supply chain creates a strong competitive advantage for businesses in crowded markets.

As the scale continues to grow, we have found that we have a greater advantage than factories. When there are too many orders, we can distribute them to several factories at the same time to produce according to our requirements. We can collaborate with different factories to meet the needs of different customers. We can showcase the quality and price of different factories to customers, providing them with more choice space. We save customers time and expenses in finding suppliers, while also reducing the sales costs of the factories. We make one-stop procurement simple.